Mixed waste is successfully converted into pyrolysis oil at Plastic Energy's facility in the Netherlands for the first time.

The chemical recycling landscape in Europe is set for a significant shift with the imminent launch of the SPEAR facility, a groundbreaking initiative that promises to revolutionise the way plastic waste is processed.

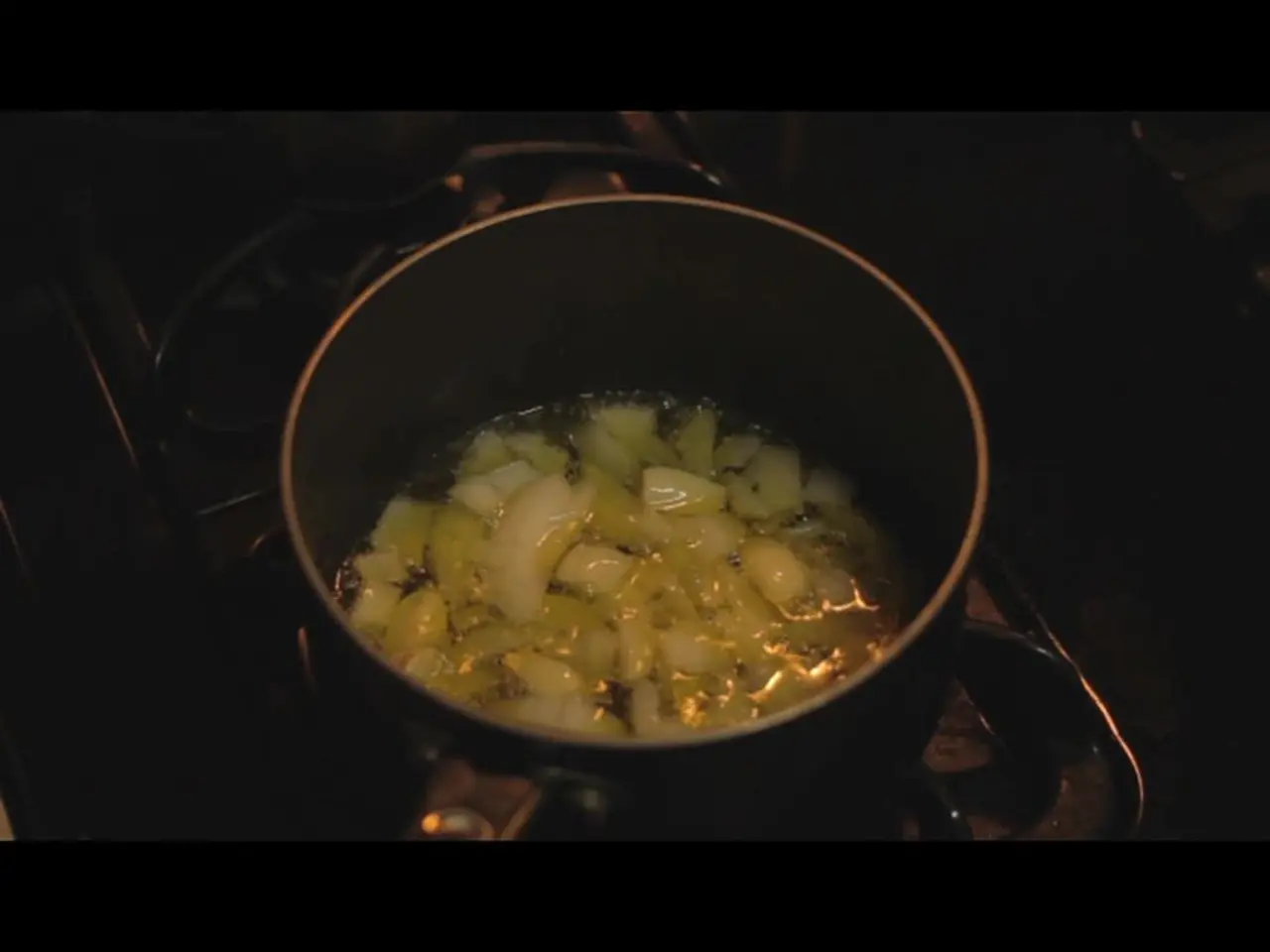

Located in Geleen, the SPEAR facility, a joint venture between Plastic Energy and SABIC, is poised to enter full commercial production later this year. The facility utilises Plastic Energy's patented TAC (Thermal Anaerobic Conversion) chemical recycling process, breaking down mixed plastics using heat in an oxygen-free environment.

This innovative process converts the mixed plastics into pyrolysis oil, a substance that can replace conventional naphtha in existing petrochemical plants. The produced oil is then used for the production of food-contact packaging, medical plastics, and various other applications.

The SPEAR facility is anticipated to recycle 20,000 tonnes of plastic waste annually, making a critical contribution to building a circular economy by boosting recycling rates, reducing CO2 emissions, and demonstrating innovation and scale.

The facility's launch comes at a time when the need for improved plastic recycling is more pressing than ever. According to the European Commission, less than 30% of European plastic waste is currently recycled. Recycling polyolefins in Europe is almost twice as expensive as producing virgin polyolefins, highlighting the urgent need for more efficient and cost-effective solutions.

The OMV expansion of its ReOil technology at its Schwechat refinery aims to convert 16,000 metric tons of hard-to-recycle mixed plastic waste into chemical feedstocks annually. Companies involved in chemical recycling technology for hard-to-recycle packaging waste in Europe include Asahi Kasei, Nouryon, Röhm, and others, all of whom are actively engaged in developing and applying sustainable chemical solutions and recycling-related innovations.

The German state of North Rhine-Westphalia is positioning itself as a hotspot for circular economy technologies, especially chemical recycling, supporting investments and innovation in this field. At K 2025 in Düsseldorf, Asahi Kasei will present advanced recycling technologies for materials such as carbon fibers, further emphasising the growing importance of chemical recycling in Europe.

As we move towards a more sustainable future, initiatives like the SPEAR facility and the OMV ReOil expansion are paving the way for a more efficient, cost-effective, and environmentally friendly plastic recycling industry in Europe. These developments are not only crucial for meeting the EU's recycling targets but also for demonstrating the potential of chemical recycling technology to address the global challenge of plastic waste management.

Read also:

- Peptide YY (PYY): Exploring its Role in Appetite Suppression, Intestinal Health, and Cognitive Links

- Toddler Health: Rotavirus Signs, Origins, and Potential Complications

- Digestive issues and heart discomfort: Root causes and associated health conditions

- House Infernos: Deadly Hazards Surpassing the Flames